Natural gas installations

![]()

-

Meraas execution’s services include the installation of Natural Gas Networks in residential, commercial and industrial buildings, including design, supply, installation and maintenance.

-

Meraas implementation is characterized by a qualified and highly experienced team in the installation of natural gas, where the team is trained on the latest technologies and international standards in this field.

-

Meraas execution uses the latest tools and equipment in the installation of natural gas, which ensures the quality of Service and the safety of customers.

Regarding the implementation and maintenance of centralized gas networks:

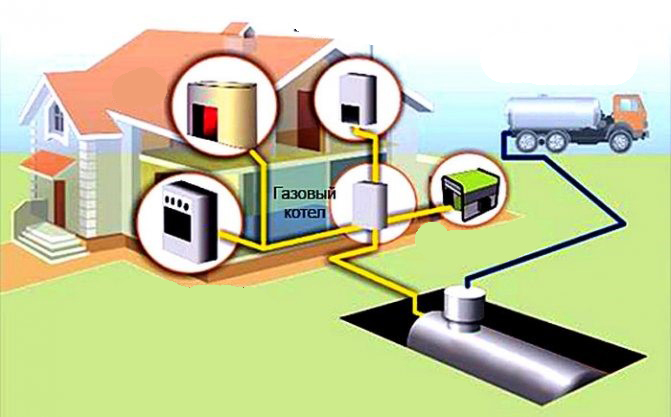

– Extension of Central Gas Networks for houses, villas, residential towers, palaces, factories, restaurants, commercial centers and tourist resorts.

– Testing the Central Gas Networks and systems to ensure their safety and health through a specialized technical staff.

– Operation and maintenance of the central gas with the best standards of security and safety.

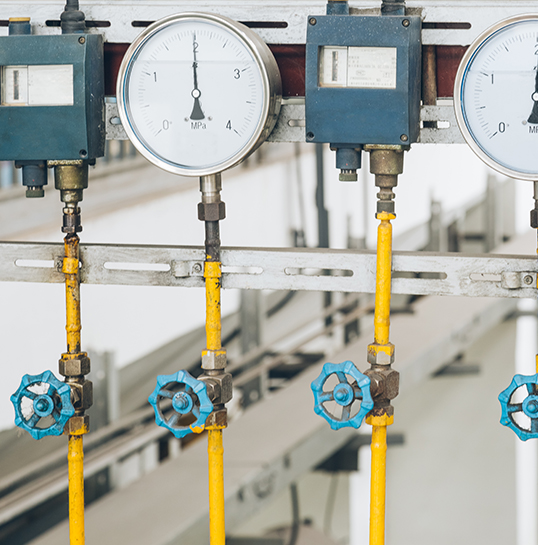

– Providing all gas supplies, including accessories, valves, pressure regulators, measuring devices and standards.

– Provision of fixed, loaded and central gas leak detectors and automatic shut-off valves.

– Providing high-quality gas meters to read The liters consumed.

– Design and development of safety systems and gas networks in homes, villas, towers, residential and commercial complexes

– Installation of centralized control systems that control the operation and shutdown of gas lines through the latest software and advanced devices.

– Linking security and safety systems with smart systems.

– Designing gas network plans for residential and commercial complexes.

– Designing security systems schemes in residential, commercial and industrial complexes

Comprehensive warranty on the network and its components

There has never been any problem or malfunction in any of the gas extensions and networks that we have established in the execution facilities during the previous years, due to:

-

Our technicians and workers have the highest level of competence, training and experience

-

We use the best hardware, accessories, valves, iron and stainless steel gas pipes and deal with the best manufacturers and suppliers.

-

We test the entire network before commissioning to make sure there is no malfunction or problem with the gas flow cycle.

-

We provide the customer with tips and instructions for the optimal operation of the gas network to avoid any malfunction caused by misuse.

-

We offer our customers a comprehensive guarantee on the gas extension network and all devices including filters, valves, regulators, leak detectors, control panels and distribution, and we are committed during that period to fix any problem that occurs in the network and in case of a malfunction of any of the devices we replace it immediately during the warranty period without incurring any additional expenses or fees

Operation and maintenance of networks

-

We have operation and maintenance contracts in which we supervise the gas installations to ensure that the distribution network works at full capacity without any malfunctions.

-

We also provide maintenance services (one visit) to repair any malfunction and replace spare parts, whether the network has been established by US or by any other company.

-

We have a team specialized in repairing emergency malfunctions and detecting any leaks or smuggling in pipes or valves.

Advantages of central gas extensions

-

Security

As we explained earlier, in the implementation of gas installations, one of the most important features is that they provide integrated safety systems in gas networks … in case of network smuggling, leak detectors and sensors send a signal to the main valve, which in turn automatically shuts off the gas from the network immediately without the need for any human intervention.

We also install sound and light alarms and connect them with sensors to alert of the presence of gas smuggling in the network.

As for the gas tank, it is made of very rigid materials that withstand significant pressure and high temperatures, it has safety valves.

-

Peace of mind

In case of large consumption, Central Gas provides peace of mind from changing gas cylinders every several days or even every other day for palaces, villas, residential buildings or restaurants and hotels. The need to refill the tank is usually between 6 months to a year, depending on the tank capacity and the amount of consumption.

-

Savings from packaging cost differences

When refilling the gas tank through the private gas company, only the calculation of the number of liters added is paid, unlike gas cylinders, in which about 10% of the gas is wasted when changed.

Frequently asked questions about central gas extensions we receive from our customers

-

Which stage of construction is considered optimal for communication with you for gas extension

You can communicate with us at any stage of construction, whether before starting the construction phase, before finishing, or even after that, and it is preferable that you communicate with us before starting construction for our engineering department to review the plan to determine the location of the tank and the places to extend the network. If this is not possible, we will send a technician to inspect the building to see how ready it is.

-

How to determine the professionalism of any central gas extension company before hiring them to work

You can easily determine this by: viewing the commercial register and official documents, requesting a previous business, visiting the company’s headquarters. Where there are many fictitious companies that do not have an official headquarters and are just papers only, sign an official contract that describes in its terms all the details of the network, warranty, type, methods and payment dates.

. Questions about central gas tanks we receive frequently from our customers at Meraas execution

-

How to order a gas tank

You can order a gas tank by contacting us at we will supply the tank and install it in case we are contracted to extend the network. One of our technicians will inspect the site to ensure that the conditions for installing the tank are met, with the termination of all contractual procedures with the private gas company.

-

Is the use of gas tanks safe

There is absolutely no fear of using gas tanks, as they are made of treated iron and are designed to withstand extreme pressure and high temperatures up to 67.5 degrees Celsius and minus 20 degrees Celsius, and the welding of each gas tank is X-ray tested to ensure that there is no technical problem in it, and a hydraulic test of the tank is also done, and it is tested one last time before supplying it to the customer to make sure that there is no leakage in it.

There is also a safety valve in the tank to adjust the pressure inside it with different weather temperatures and the expansion of liquefied gas inside, and another valve for emergency gas discharge.

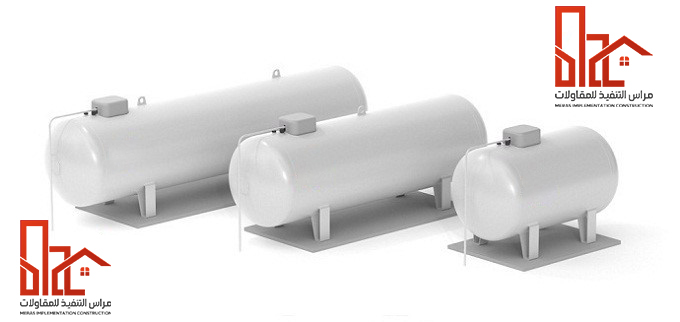

What is the difference between a tank visible above the ground and a tank buried underground, and which one is better

There is no difference in the mechanism of operation of above-ground or underground tanks, and the choice between them is based on the customer’s desire, after the availability of conditions and determining the appropriate sizes for him based on the area of the place to avoid rejection from the private gas company.

Some customers prefer buried cabinets because they do not occupy a large space with monsters or the courtyard of the building and do not conflict with the decorations of the place.Get in touch with us now at the execution service on one of the following means of communication to talk to one of our customer service representatives to answer any of your inquiries about the extensions of the central gas network

E-mail : info@merasconst.com

Whatsapp : 009660592886353

The parts that make up the central gas tank

Gas tanks are manufactured from specially treated steel plates to withstand extreme pressure, shocks and high temperatures that lead to the expansion of liquefied gas inside the tank.

Any central gas tank consists of several main parts, each of which has a function in its efficient and safe operation

-

The Tank Bowl itself:

It is a horizontal or vertical cylinder of two spherical parts connected to each other, and the volume of the vessel is according to the tank’s liter capacity, and liquefied gas is filled in it and takes up about 90% of the tank body

- Gas exit valve

(Service wrap):

The valve through which the gas flows from the tank to the distribution network

-

Filling valve:

The valve through which the tank is filled with gas by the tanks of the national gas company

-

Safety valve:

Responsible for monitoring the pressure level inside the tank and discharges any pressure above the permissible limit automatically

-

Discharge valve:

Responsible for the discharge of gas from the tank in emergency situations

-

Pressure gauge:

Responsible for measuring the pressure inside the tank

-

Liquid Level Gauge in the tank:

A meter through which the amount of liquefied gas inside the tank is read from zero to 95% and a number of those parts and valves are located inside a box.

There is also a metal plate installed on the tank in which the factory data, date of manufacture, tank capacity, dimensions and technical specifications are indicated.

Types of gas tanks

Types of gas tanks

The capacity of gas tanks is determined based on the size of the tank whether it is visible above the ground or buried underground, as the capacity of buried gas tanks is almost twice as much as their apparent counterparts.

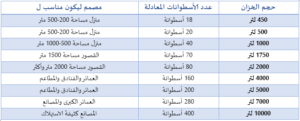

Types and capacity of central gas tanks:

-

450 L vertical above-ground gas tank with a height of 135 cm and a diameter of 75 cm

-

The price of a 500 liter vertical buried gas tank with a height of 170 cm and a diameter of 80 cm

-

The price of a 1000 liter above-ground horizontal gas tank with a length of 221 CM and a diameter of 80 cm

-

The price of a 1000 liter vertical buried gas tank with a length of 195 cm and a diameter of 110 cm

-

The price of a 1750 liter horizontal buried gas tank with a length of 262 CM and a diameter of 110 cm

-

The price of a 2000 liter above-ground horizontal gas tank with a length of 281 CM and a diameter of 100 cm

-

The price of a 4000 liter above-ground horizontal gas tank with a length of 387 CM and a diameter of 120 cm

-

The price of a 5000 liter horizontal buried gas tank with a length of 483 CM and a diameter of 130 cm

-

The price of a 7000 liter above-ground horizontal gas tank with a length of 659 CM and a diameter of 120 cm

-

The price of a 10,000 liter above-ground horizontal gas tank with a length of 610 CM and a diameter of 150 cm

.

Any underground gas tank includes the price of a rust-resistant battery and a protective mesh that is placed above the tank.

(We do not supply the tank at the execution service unless we are contracted to extend the gas network).

——————————————————————————————————–

Choosing the right gas tank size

After inspecting the place and making sure that the requirements for installing the central gas tank are met in it, we will determine the size of the gas tank that can be installed without rejection from the private gas company (gazco) for above-or underground tanks. The client has the freedom to choose from the types that will be determined for him.

But one of the main factors determining the appropriate size of the tank is the area of the place where it will be installed and the amount of expected gas consumption, whether it is domestic, commercial or industrial.

Small tanks with a capacity of 450 liters up to 2000 liters are usually installed for domestic use, medium tanks with a capacity of 4000 liters up to 5000 liters for commercial use, and large tanks with a capacity of 7000 liters up to 10,000 liters for industrial use.

And the customer can determine the average volume of the gas tank suitable for him based on his current consumption rate of gas cylinders.

The following table shows each gas tank and its equivalent cylinders